Accurately blend chemicals during completion drill-out and production clean-out operations

Mixing chemicals for completion drill-out and production clean-out operations is both an art and a science. It’s not just about the dosages or the quality of the chemicals, you also have to blend them properly in order to get the results you need for enhanced performance.

Our specially-built mixing plants and our range of chemical and additive solutions address a variety of challenges that arise during completion and production operations, such as:

Temperature concerns

Fluid losses

Formation fracture issues

H2S problems

Bacterial challenges

Clean up and debris related well issues

Friction losses, particularly on high pressure wells

Torque and drag on extended reach laterals

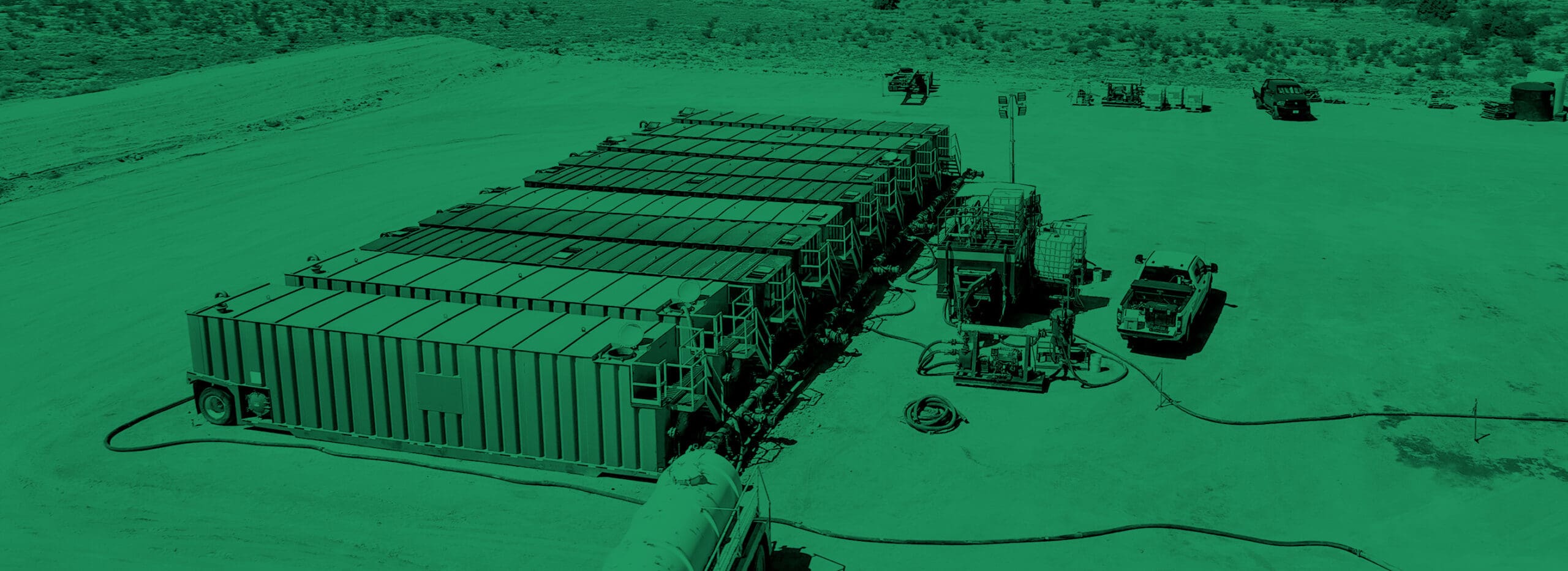

Optimizing Chemical Performance with Tornado’s Specialized Mixing Plants

With Tornado’s mixing plants, high-quality chemicals, and experienced team, you can address these challenges head on.

Properly blending chemicals with mixing plants has proven to reduce the amount of wasted chemicals while increasing their effectiveness. Our mixing plants are specially manufactured to maximize the efficacy of the chemicals for completion and production operations.